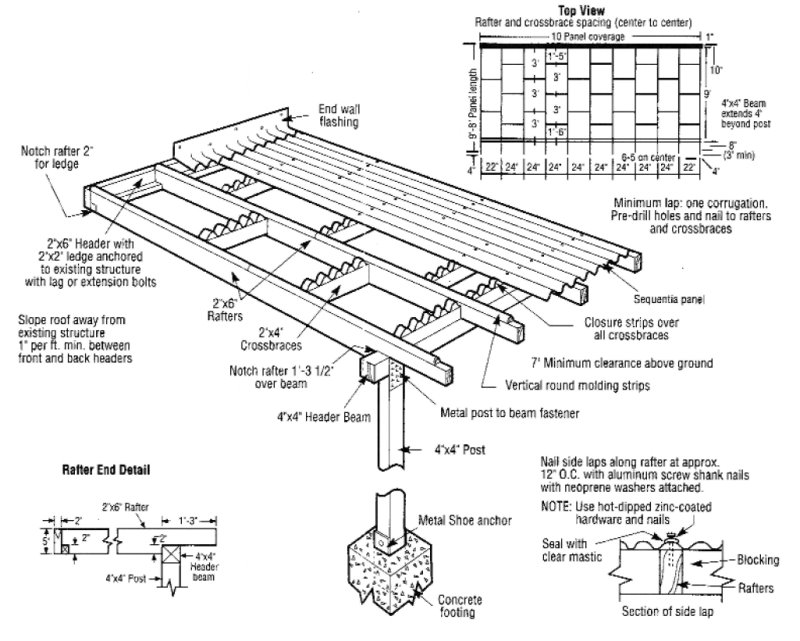

37 polycarbonate sheet installation diagram

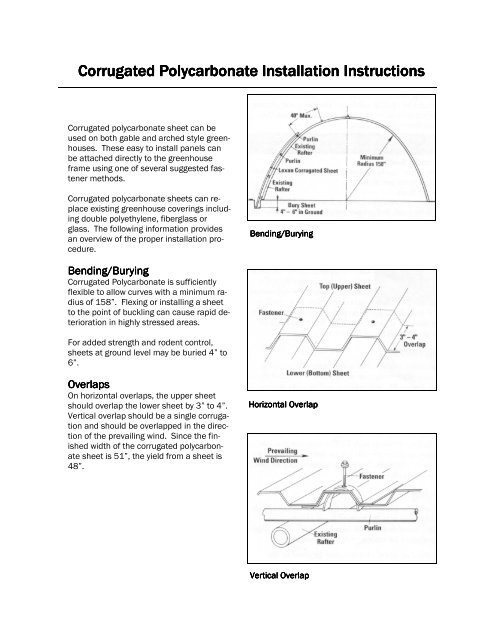

Suntuf Solar Control: Corrugated polycarbonate sheet that transmits selected percentages (20%, 35%, or 50%) of the light energy while keeping the undesired components of the energy spectrum (heat) out. The solar control feature is an integral part of the sheet and will not peel away. 1. Measure out the size of polycarbonate sheet you require and using the straight edge, mark out the lines to be cut. 2. Place the sheet on a stable surface and clamp down. We recommend to use a timber block to cushion the impact of the clamp. 3. Begin cutting. Polycarbonate is a material that is very easy to cut so

Here at The Plastic People, one of our customers' most common queries is about polycarbonate roofing panels and installation. Polycarbonate sheets have been designed for both domestic and commercial roofing - and there is a wide range of fittings and systems that support this plastic material.. You are likely to come across polycarbonate roofing on an almost daily basis.

Polycarbonate sheet installation diagram

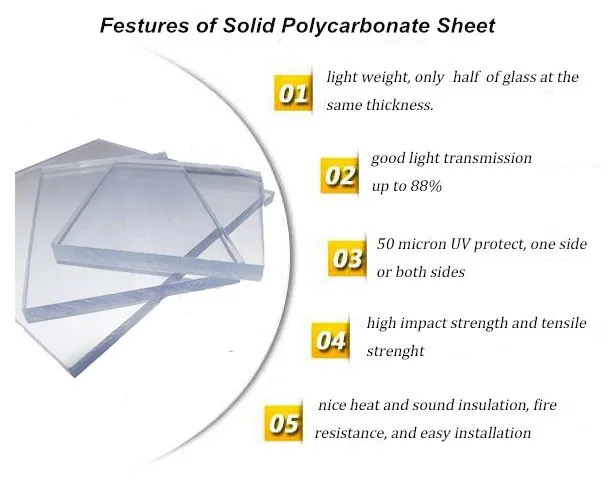

The following diagram shows the relative impact strength of Polycarbonate when compared to the impact strength of other commonly used plastics such as ABS, Polystyrene (PS), or Nylon. Image From ptsllc.com. Another feature of polycarbonate is that it is very pliable. September 23, 2021 - Polycarbonate sheeting has become an increasingly popular material for roofing, windows, and canopies. Find out everything you need to know about installing polycarbonate sheeting for the best results. Laserlite recommends a distance of 1m is kept between the sheets and the heater, adequate ventilation at all times and temperature to be below 90ºC beneath the sheeting. If temperature underneath your sheet rises above 90ºC, immediately remove the patio heater from underneath the polycarbonate sheeting.

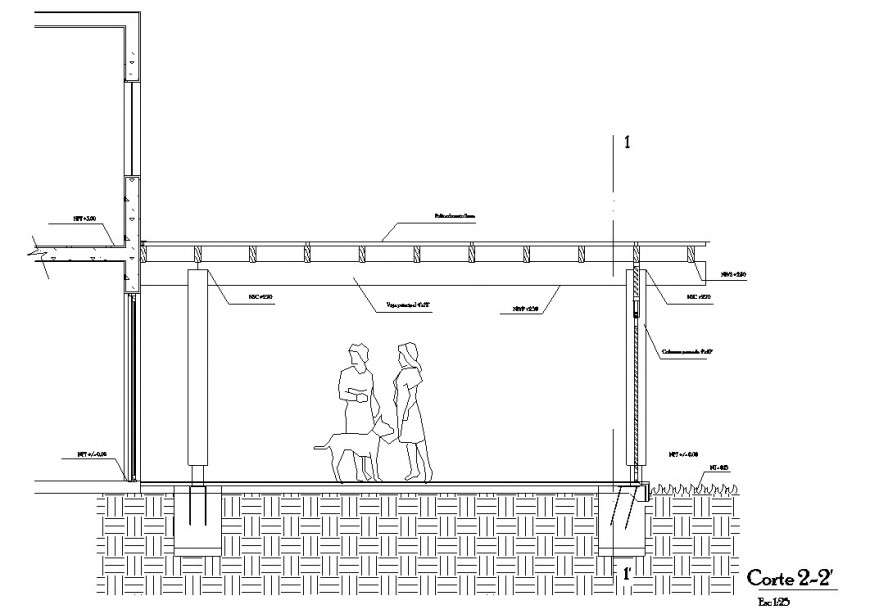

Polycarbonate sheet installation diagram. 1. Install panels on walls in a similar manner to ceiling installation. 2. Begin by installing Base Trim along bottom of wall. - If using J-Trim, drill 1/4" drain holes in bottom of trim for drainage 3. At corners, either install J-Trim vertically to finish ends of butt joints. - Or install Inside Cove Trim when panel comes to corner Most multi-wall polycarbonate sheets come with a standard UV coating on one side that is meant to protect the panel from fading or discoloration caused by the sun. Make sure this UV coating is facing outward when installing the panels. If you install the panels with the coating side in, your panels won't be protected. Multiwall polycarbonate features a UV-protected surface on one or both sides of the sheet. This UV protection prevents ultraviolet rays from deteriorating the polycarbonate, ensuring the sheet will not crack, yellow, or weaken from intense sun exposure. When installing multiwall polycarbonate, it is important to have the UV-protected surface facing Varico Ltd are trusted suppliers of polycarbonate sheets and construction products in the UK. For technical advice or quotes, please call us on 01922 455338.

This diagram is valid only when the following conditions are followed: - Correct calculation of expansion in order to provide for the necessary allowance in the framing. The thermal expan-sion coefficient is 0.0000375 in/in oF. - Where possible install the sheets with the ribs running vertically and following bending recommendation. Learn the correct step by step process for fixing polycarbonate sheets here. Panels clip together for a simple, quick installation. 16mm Triplewall Polycarbonate Roofing Sheet Bronze £14.25 - £299.46. Ideal for use in lean to conservatories, canopy roofs, carports and replacement commercial glazing applications. The Polycarbonate Store is the number one choice for Polycarbonate Sheet, Polycarbonate Sheets, Polycarbonate Roofing Sheets, Polycarbonate Discs and Polycarbonate Tubes

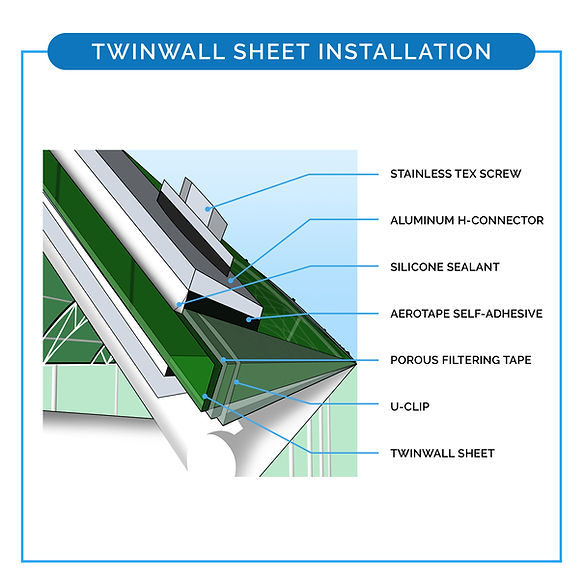

Aluminum profiles and accessories for polycarbonate sheet installation. A proper installation of polycarbonate sheets requires the use of the elements necessary to get the job done. We offer a complete range of aluminum or polycarbonate profiles , sealing and anti-dust tapes , screws …. The R Profile is designed to connect two Gallina polycarbonate sheets at a corner of a vertical installation. Laying opening, the R Profile is positioned at 180° and can be closed to make a 90°. Install by inserting the polycarbonate sheet into the R Profile running parallel with the flutes. Using the R Profile to create a roof ridge SUNLITE sheets may be cold bent or curved up to their minimum permitted radius, using polycarbonate's natural tolerance for cold forming with no need for thermal processing. Curving SUNLITE sheet beyond this minimum permitted radius induces undue stresses and strains in the glazing sheet, causing premature failure and will void the warranty. POLYGAL MULTIWALL POLYCARBONATE SHEETS USER GUIDE AND INSTALLATION INSTRUCTIONS Packaging Polygal products are generally delivered in 20' and 40' box containers, protected on both sides by polyethylene sheets against scratching, and secured to prevent damage from movement within the container.

With quick shipping, low prices, & great customer service, Greenhouse Megastore is your top online source for greenhouses and garden supplies. Shop with us today!

Tips and diagrams that show you how to install polycarbonate panels and use all the hardware and accessories for proper construction

This video is part of the AmeriLux FAQ Series and answers the frequently asked question: How can I get my polycarbonate H- or U-profiles to slide onto my mul...

Installation Guide Safety Do not step directly on the panel. Use stepping boards. Work according to local safety regulations codes. Handling and Storage Store in a dry shaded place, protect from direct sunlight and rain. Avoid covering the sheets with heat absorbing materials. Avoid contact or environment of chemicals. Protect the sheets from any physical damage.

Macrolux Multiwall Polycarbonate Sheet LOAD RESISTANCE This diagram is valid only when the following con - ditions are followed: • Correct calculation of expansion in order to provide for the necessary allowance in the 0.0000375 in/in °F. • Install the sheets with the ribs running vertically. For bent applications, the ribs should bend ...

May 8, 2018 - Install the sheets without stress – that is; don’t pull, tension or twist the sheets. Next move up to the next purlin screwing across the sheet in the same direction. Place screws as per the below diagram and continue this for all the ‘internal purlins’ or ‘mid purlins’.

Palram is a global manufacturer of polycarbonate and PVC sheets, polycarbonate panels and panel systems for varied roofing and cladding applications

Birchwood Trading offer a range of roofing products, including polycarbonate glazing, glazing bars, canopies, dome rooflights and tapco slates.

How to install polycarbonate roofing onto a timber framework to make a carport, This video shows the step by step instructions using the Hawk glazing bar sys...

Want some advice on how to install your polycarbonate sheets, or interested in finding out more about our product range, take a look at our guides & tips.

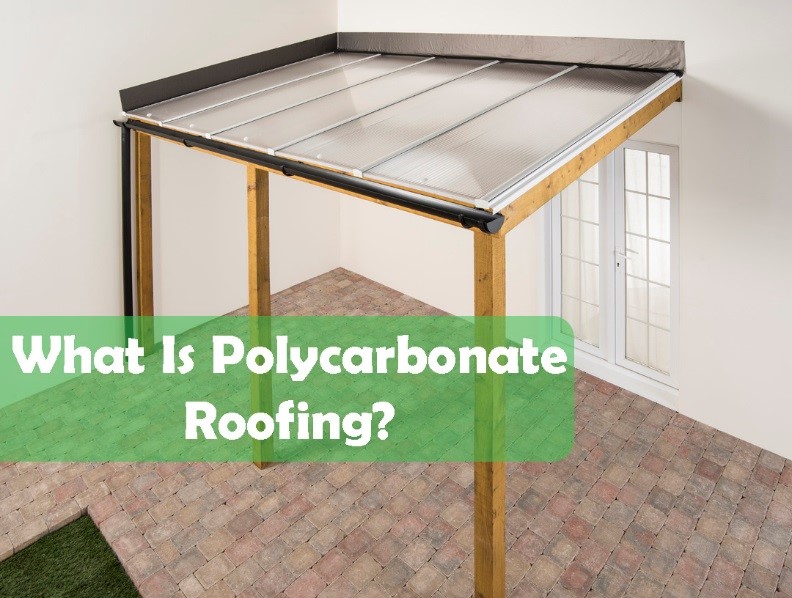

Polycarbonate sheeting is one of the most popular forms of roofing in the UK. Incredibly versatile, it can be seen on a wide variety of structures including conservatories, garages, carports, canopies, lean-tos and even extensions.Polycarbonate is highly favoured by homeowners thanks to its low price point, solid durability, and straightforward installation.

January 1, 2015 - Have you been looking for a new plastic supplier? Click now to learn more about our services and wide selection of made-to-order materials, supplies, and tools today.

Apply H-Bar Gasket to entire length of sheet (diagram C) and push sheet into the already secured H- Bar as diagram D. A rubber mallet may be used to tap sheet with gasket applied into the H-Bar. For ease of installation of long sheets, 'Ezy-Glide' spray may need to be applied to the gasket. Apply H-Bar Gasket to the other side of sheet.

Installation Guide Congratulations on your purchase of Axiome® multiwall polycarbonate sheet! These Axiome® multiwall polycarbonate panels have been specially prepared for your use, but it is essential that you read the following notes carefully to ensure that you get the very best out of them. 1. Upon receipt of your Axiome® panels, they must be stored in a clean, dry area to prevent ...

Offering a nationwide 'Cut to Size' service and the widest choice of roofing sheet, rooflights and roofing accessories available in the UK, Ariel Plastics provides specialist roofing and glazing solutions for any application. The company’s market proven portfolio includes extensive Roofing ...

How to install polycarbonate roofing onto a timber framework to make a carport, This video shows the step by step instructions using the Hawk glazing bar sys...

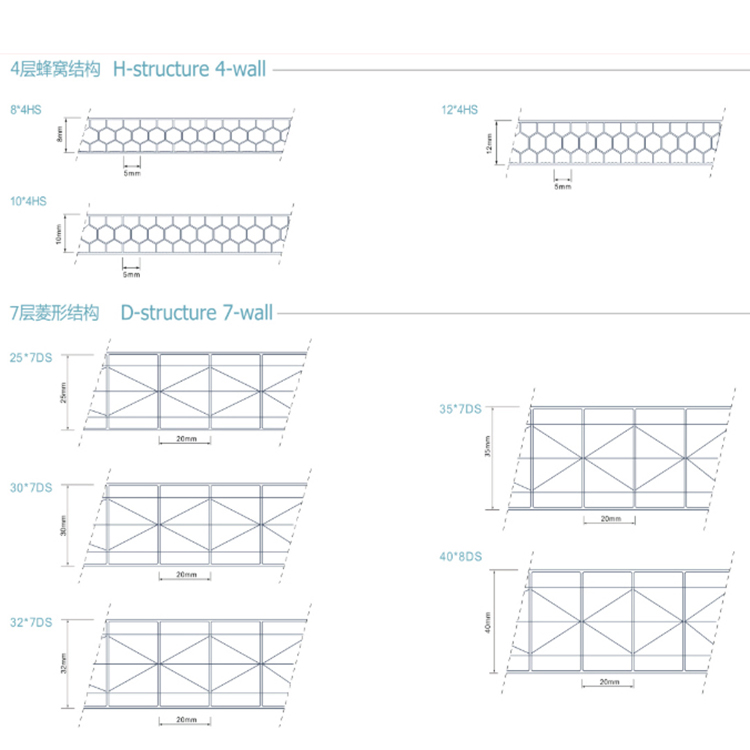

SUNLITE X-lite / SUNLITE V-structure multiwall polycarbonate sheets, with an internal diagonal structure, offer an excellent balance between weight and structural strength, and improved thermal insulation properties.This is the strongest and thickest version available. These robust multiwall sheets can carry loads better than any other multiwall polycarbonate alternative.

Wood Frame Design for Multi-Wall Polycarbonate: The simplest way to frame for multi-wall polycarbonate is to set studs and rafters 24-1/8" on center. This dimension will allow for a slight gap between sheets, required for fasteners and sheet movement.

SUNLITE sheets may be cold bent, or curved up to their minimum permitted radius, using polycarbonate's natural properties, without need of a thermal process. Curving SUNLITE sheet beyond this minimum permitted radius induces undue stresses and strains in the glazing sheet, causing premature failure and will void the warranty. Table 2.

August 31, 2021 - If you want to fit a polycarbonate roof, you’re going to need to know the why, what and how-to. This guide is dedicated to helping you know how to fit polycarbonate roofing to ensure you’re set with the tools you need for this project. Table of contents: What is polycarbonate roofing?

Step-by-step Polycarbonate Sheet Installation Roofs should always be designed with a minimum slope of 5° to allow adequate rainwater run-off. Ensure that the UV protected surface (marked on protective film) of the Polycarbonate sheet is to the outside. 50mm of protective film should be peeled back from the edges of the sheet before ...

INSTALLATION Stiff fixing by means of adhesive or putty is to be avoided. If using sealants, contact your sales representative for recommended sealants. Exposed top and bottom ends of a sheet must always be sealed by means of the proper polycarbonate "U" profiles or an adhesive aluminum tape to prevent dust and dirt penetrating inside the ribs.

Installation Tips. 1. Make sure that you have purchased greenhouse polycarbonate that is UV protected on at least one side. This is the side that will be out toward the sun. The UV protection is what gives the polycarbonate its extended life. Polycarbonate sheets with UV protection will carry a 10 – 20 year warranty.

Polycarbonate sheet. This article shall focus on polycarbonate sheets, and the various techniques and equipment that are used to mold them into the desired final product. Polycarbonate Sheet Bending Machine and Equipment. Since there are different sheet bending techniques, it follows that the machine and equipment to be used are different.

Laserlite recommends a distance of 1m is kept between the sheets and the heater, adequate ventilation at all times and temperature to be below 90ºC beneath the sheeting. If temperature underneath your sheet rises above 90ºC, immediately remove the patio heater from underneath the polycarbonate sheeting.

September 23, 2021 - Polycarbonate sheeting has become an increasingly popular material for roofing, windows, and canopies. Find out everything you need to know about installing polycarbonate sheeting for the best results.

The following diagram shows the relative impact strength of Polycarbonate when compared to the impact strength of other commonly used plastics such as ABS, Polystyrene (PS), or Nylon. Image From ptsllc.com. Another feature of polycarbonate is that it is very pliable.

0 Response to "37 polycarbonate sheet installation diagram"

Post a Comment