40 ttt diagram for eutectoid steel

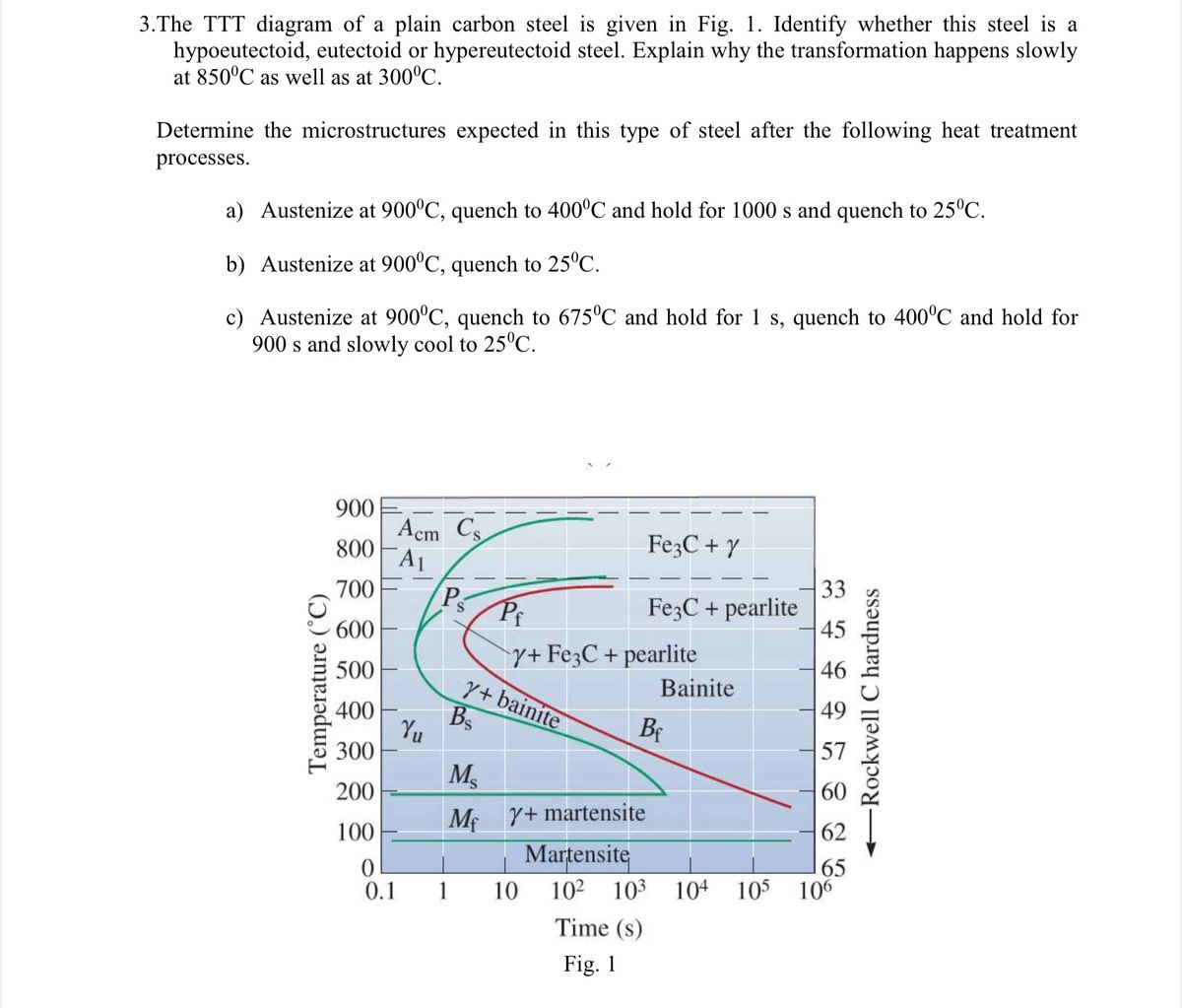

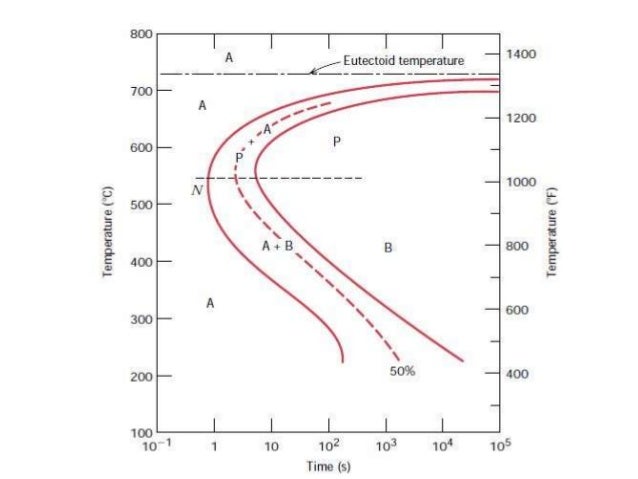

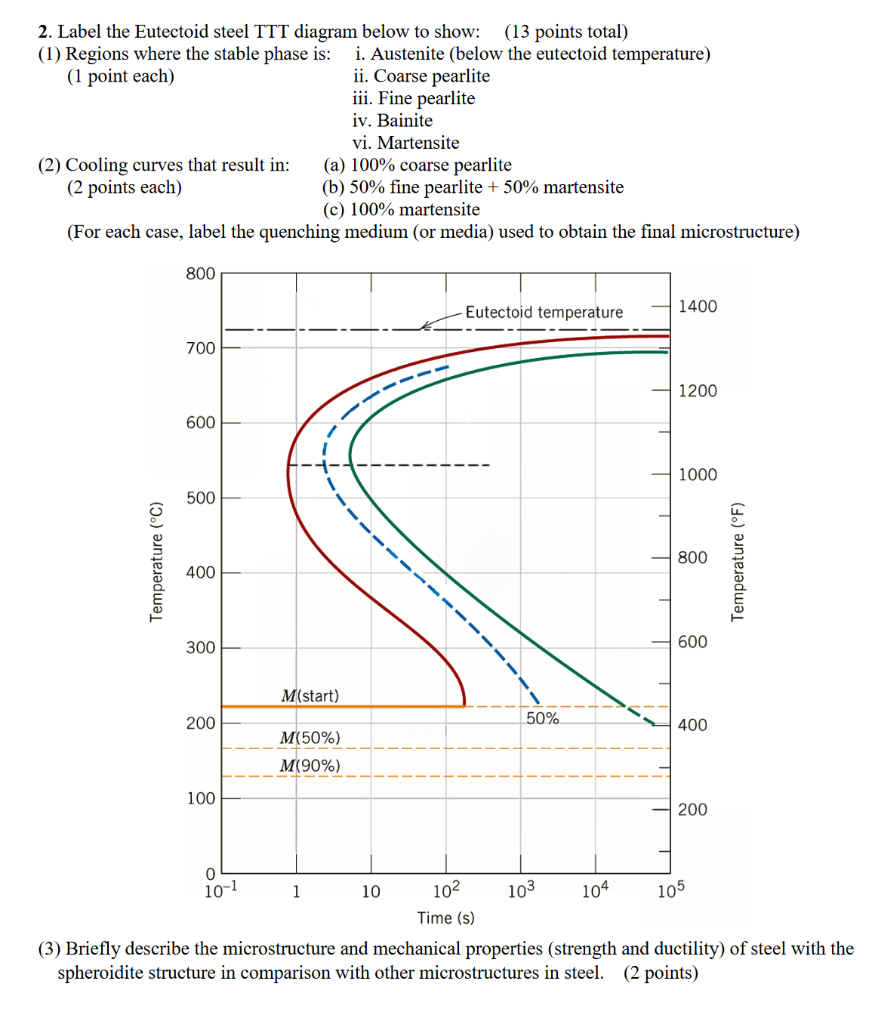

TTT Diagram On the other hand, TTT diagram is a more practical diagram. It shows what structures can be expected after various rates of cooling. It graphically describes the cooling rate required for the transformation of austenite to pearlite, bainite or martensite. TTT diagram also gives the temperature at Consider the TTT diagram and phase diagram for a eutectoid steel. TTT If a specimen of this steel is solutionized (aka, annealed to equilibrium) at 750°C for 1 day and then rapidly quenched to 300oC where it is held for 5 days.

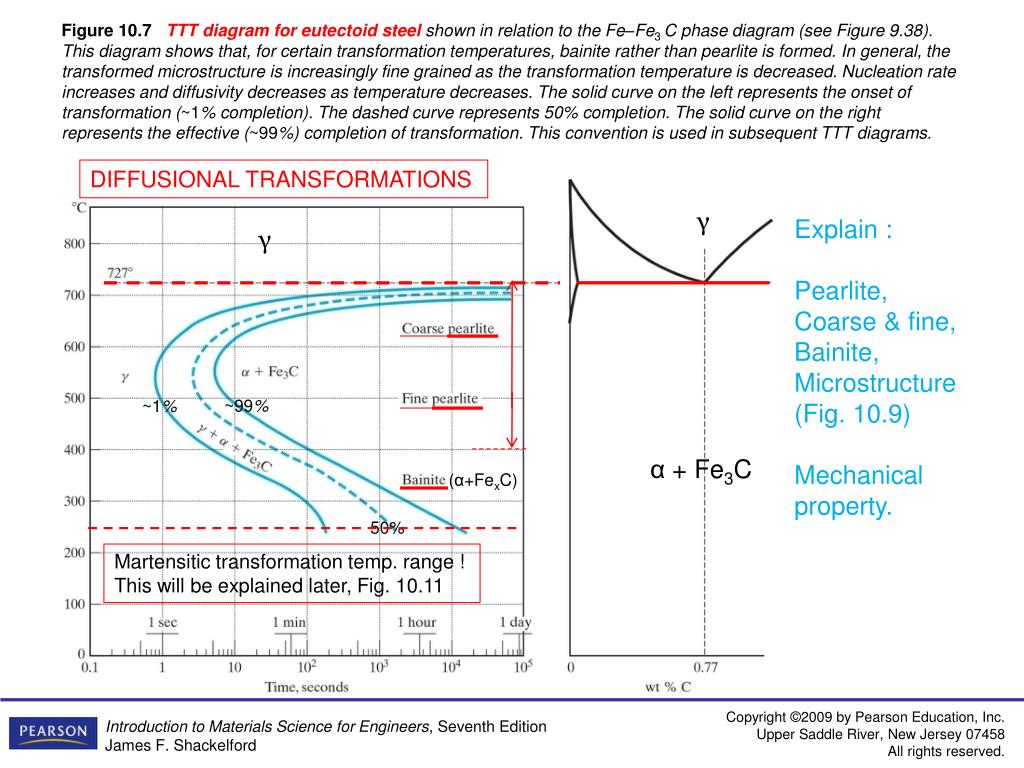

Determination of TTT diagram for eutectoid steel Davenport and Bain were the first to develop the TTT diagram of eutectoid steel. They determined pearlite and bainite portions whereas Cohen later modified and included M S and M F temperatures for martensite. There are number of methods used to determine TTT diagrams. These are salt bath (Figs. 1-

Ttt diagram for eutectoid steel

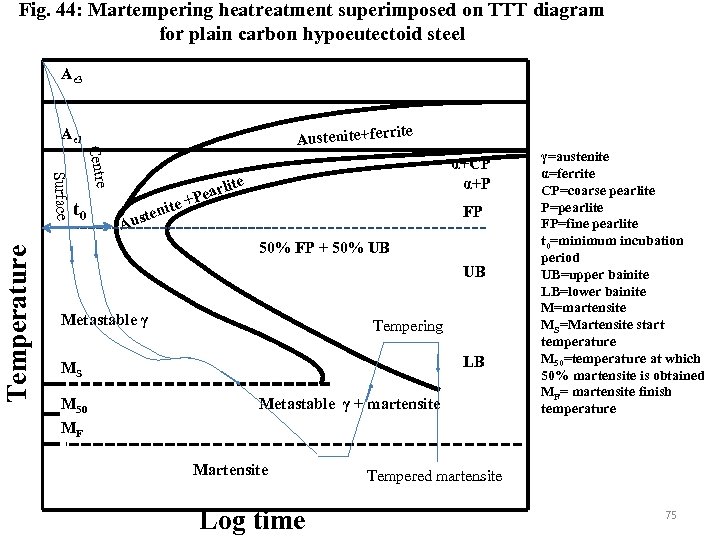

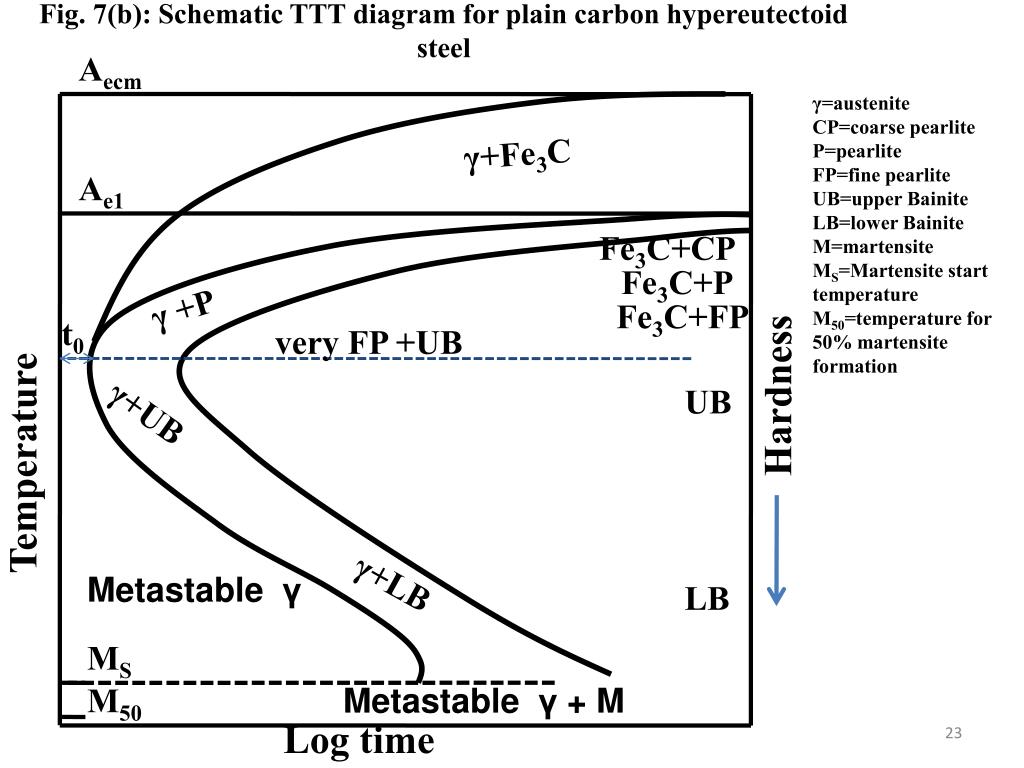

hypoeutectoid steel and by cementite in hypereutectoid steel. Schematic T TT diagrams for eutectoid, hypoeutectoid and hyper eutectoid steel are shown in Fig.", Figs. 7(a)-(b) and all of them together along with schematic Fe-Fe3C metastable equilibrmm are shown in Fig. 8. Nov 18, 2013 · Complete TTT (isothermal transformation) diagram for eutectoid steel. 38. Time Temperature Transformation (TTT) Diagram • Below A1 , austenite is unstable, i.e., it can transform into pearlite, bainite or martensite. • The phases finally formed during cooling depend upon time and temperature. TTT Diagram For Eutectoid Steel ( Isothermal Transformation Diagram ) Time-Temperature-Transformation (TTT) diagram or S-curve refers to only one steel of a particular composition at a time, which applies to all carbon steels. This diagram is also called as C-curve isothermal (decomposition of austenite) diagram and Bain’s curve.

Ttt diagram for eutectoid steel. Davenport and Bain were the first to develop the TTT diagram of eutectoid steel. They determined pearlite and .TTT Diagram • The TTT digrams for hyper-eutectoid steels will differ from that of eutectoid steels • The TTT diagrams for hyper-eutectoid steels will have an additional curve to show the precipitation of cementite from martensite ... Mechanical Engineering questions and answers. The TTT diagram for a 1077 eutectoid steel is given explain each heat treatment process: a) To form 50% Coarse Bainite -50% Martensite. b) To form 50% Coarse Pearlite -50% Fine Bainite. Temperature C) Temperature () 20- 1 1 10 102 103 104. TTT diagram of hypoeutectoid and hypereutectoid steels Sep 14, 2021 · Presented above is the TTT-diagram for eutectoid steel. For each composition, there will be a slight variation in diagram curves. TTT diagram of steel indicates the time-temperature and transformation curve. This means transformation is dependent upon time, temperature, and cooling mechanism. Difference between phase diagram and TTT diagram of steel

the iron-carbon alloy system. A sample of the eutectoid composition is cooled from a single-phase region (γ) to a temperature (T) below the eutectoid temperature (T E). The following diagram shows a part of the iron-carbon phase diagram. Concentrations C 1, C 2, C 3, C 4 are various equilibrium ( stable as well as metastable ) concentrations ... diagram for the eutectoid steel as seen in Figure 4. This particular diagram presents the rates for isothermal (constant temperature) transformations of a eutectoid steel. In these diagrams the y-axis is temperature and the x-axis is time. In this instance the logarithm of time is used. As seen on this diagram at temperature above 723℃ (1,333℉) Jan 22, 2013 · TTT diagram of eutectoid steel and martensitic transformation. 1. Muhammad Umair Bukhari Engr.umair.bukhari@gmail.com http://onlinemetallurgy.com. 2. T-T-T diagram is plotted for different length of times and temperature These curves gives us the information of transformation for different phases With the help of T-T-T diagram we can control the phase transformation by changing the conditions. TTT Diagram For Eutectoid Steel ( Isothermal Transformation Diagram ) Time-Temperature-Transformation (TTT) diagram or S-curve refers to only one steel of a particular composition at a time, which applies to all carbon steels. This diagram is also called as C-curve isothermal (decomposition of austenite) diagram and Bain’s curve.

Nov 18, 2013 · Complete TTT (isothermal transformation) diagram for eutectoid steel. 38. Time Temperature Transformation (TTT) Diagram • Below A1 , austenite is unstable, i.e., it can transform into pearlite, bainite or martensite. • The phases finally formed during cooling depend upon time and temperature. hypoeutectoid steel and by cementite in hypereutectoid steel. Schematic T TT diagrams for eutectoid, hypoeutectoid and hyper eutectoid steel are shown in Fig.", Figs. 7(a)-(b) and all of them together along with schematic Fe-Fe3C metastable equilibrmm are shown in Fig. 8.

0 Response to "40 ttt diagram for eutectoid steel"

Post a Comment