41 coal fired power plant process flow diagram

PDF Electricity Generation Baseline Report Coal-fired capacity saw its last notable additions in 2010 as plants planned before the financial crisis of 2008 came online. 8. Changes in electricity markets, fleet composition, and usage patterns in recent years have seen power plant operators and engineering, permitting, and construction vendors adapt... PDF Power Plant Engineering 4.2.1 Power Station Design 4.2.2 Characteristics of Steam Power Plant 4.3 Coal Handling 4.3.1 Dewatering of Coal 4.4 Fuel Burning Furnaces 4.4.1 A power plant may be defined as a machine or assembly of equipment that generates and delivers a flow of mechanical or electrical energy.

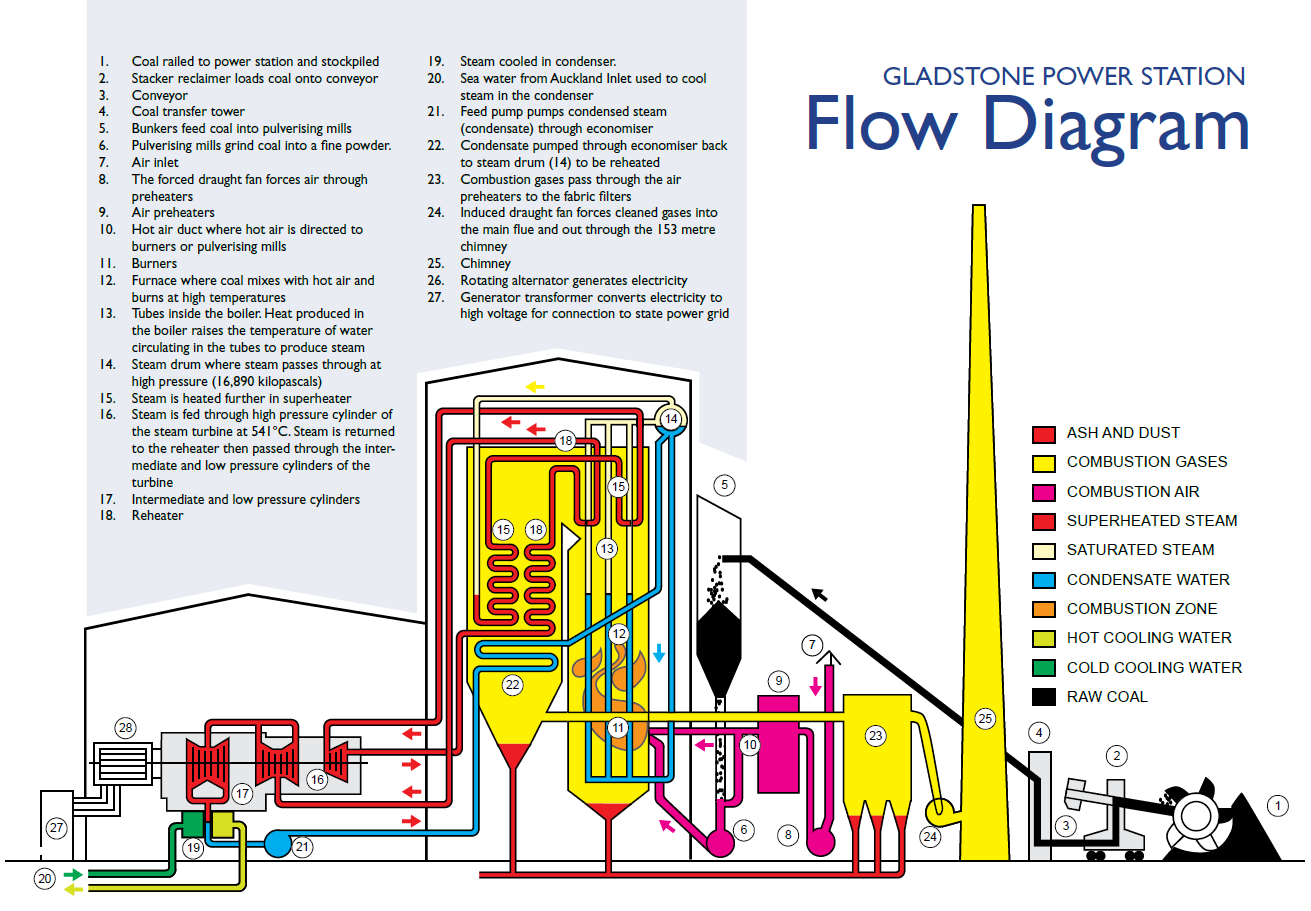

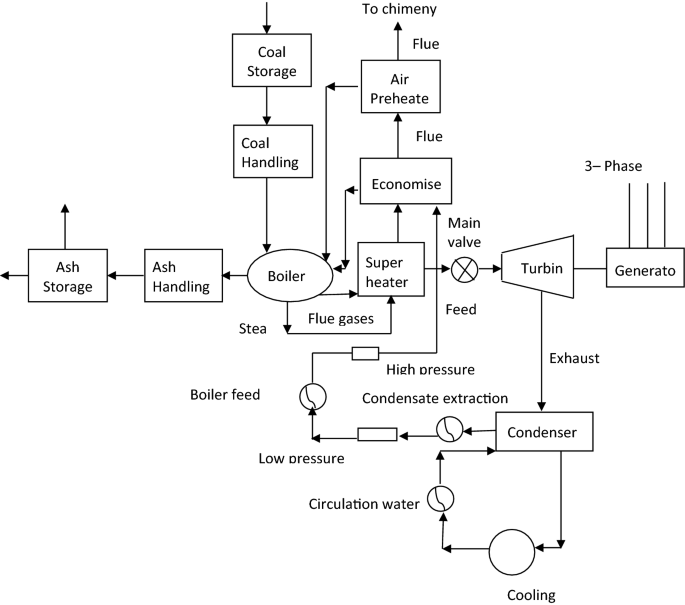

Flow diagram - Wikimedia Commons A process flow diagram (PFD) is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. Water flow diagram of a steam cycle power plant. Water cycles of a coal fired power station.

Coal fired power plant process flow diagram

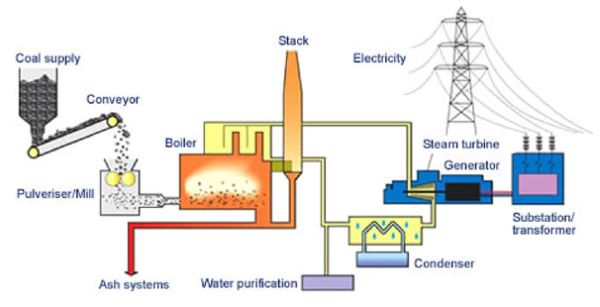

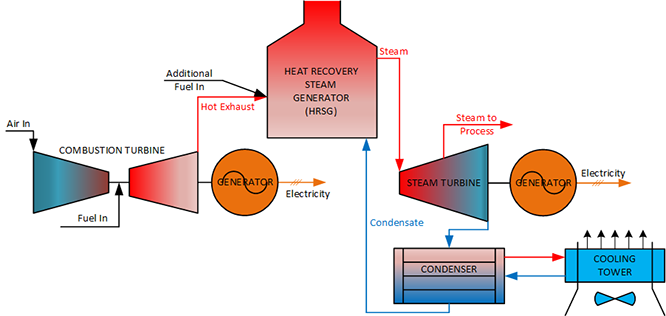

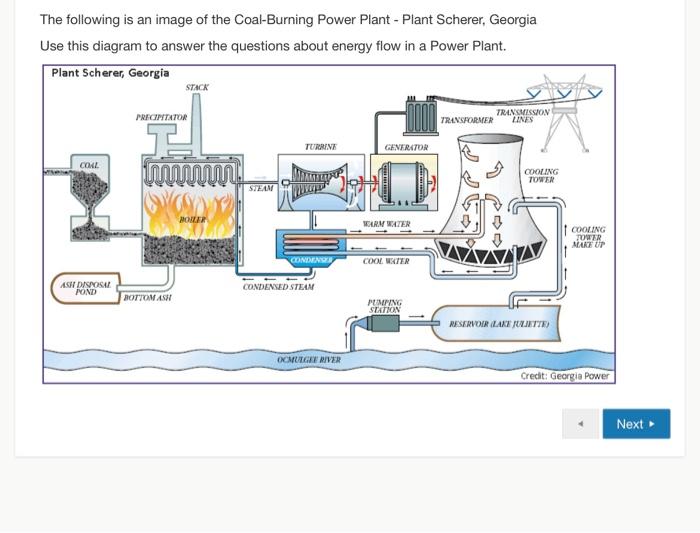

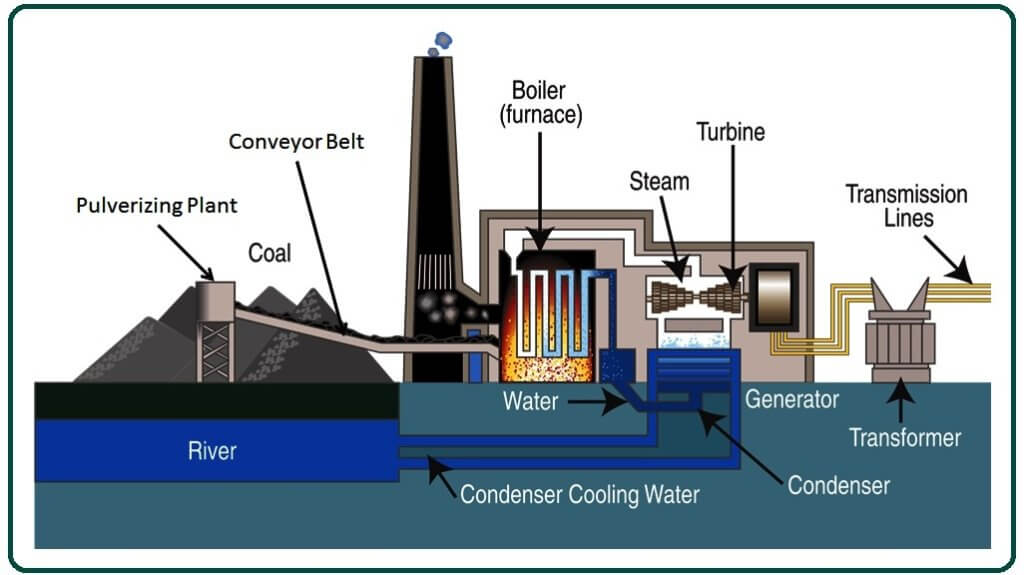

How a Coal Plant Works How a Coal Plant Works. Coal-fired plants produce electricity by burning coal in a boiler to produce steam. The steam produced, under tremendous pressure, flows into a turbine, which spins a The steam is then cooled, condensed back into water and returned to the boiler to start the process over. PDF Retrofitting of Coal-Fired • options for federal coal-fired power plant CO2 emissions mitigation research management principally through government/industry partnerships.1. • improvements in post-combustion capture options to include better amines and advanced flue gas capture processes, almost all of which are in the early... An Overview of Combined Cycle Power Plant A Combined Cycle Power Plant produces high power outputs at high efficiencies (up to 55%) and with low emissions. Under normal conditions the inlet system has the capability to process the air by removing contaminants to levels below those that are harmful to the compressor and turbine.

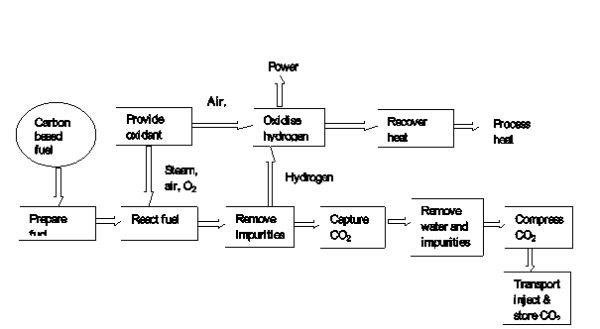

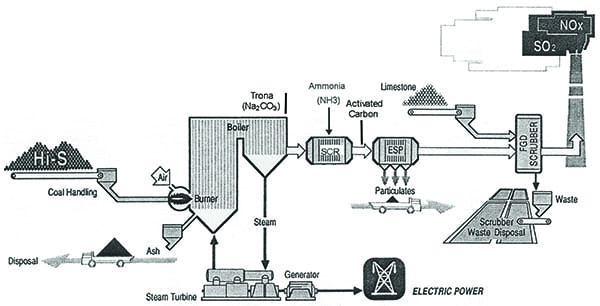

Coal fired power plant process flow diagram. The Different Types of Power Plants | 3. Coal-run power plants Coal run or coal-fired power plants burn coal to convert water into steam. A 1000MW coal power plant burns through 9000 tons of coal per day. This process releases very high amounts of pollutants into the air. PDF Figure 2.1 : Process Water Flow Diagram for 2000 MW inland Coal... Figure 11.1 : Process Flow Diagram of Generic FGD Waste Water Treatment Plant. For a four unit 2000MW coal-fired power plant, maximum makeup requirements are typically around 4600 m3/day. To produce this amount of makeup water would require a raw water supply in the region of 5000... Figure 4: Post-combustion CO2 removal from a coal-fired power plant... Coal power plants have multiple points for injecting solar heat, such as boiler feedwater pre-heating, direct steam Compared to a conventional coal-fired Rankine cycle power plant, CO2 emissions are reduced by 47% using this configuration. Figure 5: Process flow diagram for a solar-assisted... PDF Large | Capture Technology at the Abbott Coal-Fired Power Plant process flow diagram, process descriptions, material balances, utility consumption; emissions and effluents; (iii) equipment list; (iv) process data sheet for all equipment and mechanical datasheets and piping and instrumentation diagrams. The Abbott Power Plant will provide the major utilities for the...

Hydroelectric Power: How it Works | U.S. Geological Survey Actually, hydroelectric and coal-fired power plants produce electricity in a similar way. In both cases a power source is used to turn a propeller-like piece called a turbine. Take a look at this diagram (courtesy of the Tennessee Valley Authority) of a hydroelectric power plant to see the details PDF Microsoft Word - FINAL-NAMC-SWG_Removal_Technologies.docx Power plants can minimize selenium release through design and selection of fly ash handling and flue gas desulfurization systems. • • • Section 4.3.2.2 contains parametric cost curves for capital and operating costs, process flow diagram and assumptions for development of costs. Thermal Power Plant Components & Working... | Thermodyne Boilers How does Thermal Power Plant work? In thermal power plants, the heat energy obtained from combustion of solid fuel (mostly coal) is used to convert Thermal Power Plant consists of a whole set of steps in series for producing electricity. Thermal Power Station Process Flowchart and Diagram. Coal fired power plant - Energy Education Coal fired power plants also known as coal fired power stations are facilities that burn coal to make steam in order to generate electricity . Since they require plenty of water to be circulated in this cycle, coal power plants need to be located near a body of water. The process of coal fired plants can be...

Combined Cycle Gas Turbine Power Plant - an... | ScienceDirect Topics In comparison with coal-fired power plants, open- and closed-cycle power plants are characterized by lower investment costs. On the other hand, fuel costs (i.e., fuel price and plant efficiency) play a relatively more important role. Therefore, gas pricing is a very important issue, which ranges presently... Mapped: The world's coal power plants in 2020 Since 2000, the world has doubled its coal-fired power capacity to around 2,045 gigawatts (GW) after explosive growth in China and India. (The economic status of most of these plants has been or is now in the process of being resolved.) Meanwhile, prime minister Narendra Modi has announced... PDF Revised SCR chapter for EPA workgroup review | Fuel Type Coal Figure 2.1: SCR Process Flow Diagram [31, 32]. It is estimated that a typical 500-MW coal-fired power plant will spend approximately $2,000,0005 on a single layer of new catalyst [48]. Coal-fired boilers generally use a vertical SCR reactor, where the flue gas flows downward through the catalyst. Conventional coal-fired power plant - encyclopedia article - Citizendium This article is about Coal-fired power plants. For other uses of the term Power, please see Power (disambiguation). A conventional coal-fired power plant produces electricity by the burning of coal and air in a steam generator, where it heats water to produce high pressure and high temperature steam.

PDF Carbon capture from pulverized coal power plant (PCPP): solvent plant, when integrated with the upstream coal-fired power plant, subject to variations in the electricity load. 19. The results suggest that optimal design Firstly, the overall process block. 139. diagram and the process flow diagram of the power plant and capture plant are presented and discussed.

7.3.3. Hydrogen Production from Coal without Power... | netl.doe.gov Figure 3 is a block flow diagram for producing H2 from coal with minimal power generation. Eliminating the need for H2 fired gas turbine (GT) by switching to low or medium Btu fuel-fired boiler plant. Changing the pressure swing absorption (PSA) purge compressor to a lower head blower.

Power Plants: What Are They? (& the Types of Power...) | Electrical4U A thermal power station or a coal fired thermal power plant is by far, the most conventional Rain falling upon the earth's surface has potential energy relative to the oceans towards which it flows. This energy is converted to shaft work where the waterfalls through an appreciable vertical distance.

2. Introduction to coal fired power plant | IntechOpen The coal fired power plants generate the majority of the electricity and produce the highest rate of CO2 per A typical pulverized coal (PC) combustion power plant is equipped with three units, boiler block Figure 12 shows the flow diagram of mineral carbonation process with serpentine and olivine.

Emission from Coal Fired Power Plants 2. Introduction to coal fired power plant. Electricity can be produced by various sources such as fossil fuels, nuclear fission Figure 12 shows the flow diagram of mineral carbonation process with serpentine and. olivine. In this diagram carbonation is carried out after different pre-treatment options...

TWEST: Technology to convert coal-fired plants into energy storage... The E2S Power concept converts existing coal-fired power plants into energy storage facilities by substituting the E2S thermal energy storage system for the During the charging process, electricity from renewable sources powers the electric heaters which heat up the MGA storage blocks to a...

PDF THERMAL POWER | Section 1 Energy Efficiency and Plant Performance Preface Thermal Power Plants - Advanced Applications. Section 1 Energy Efficiency and Plant The energy conversion in a coal-fired power plant is dominantly a thermodynamic process. The flow sheet for the power generation cycle is presented in Figure 3. It shows the steam cycle of the power...

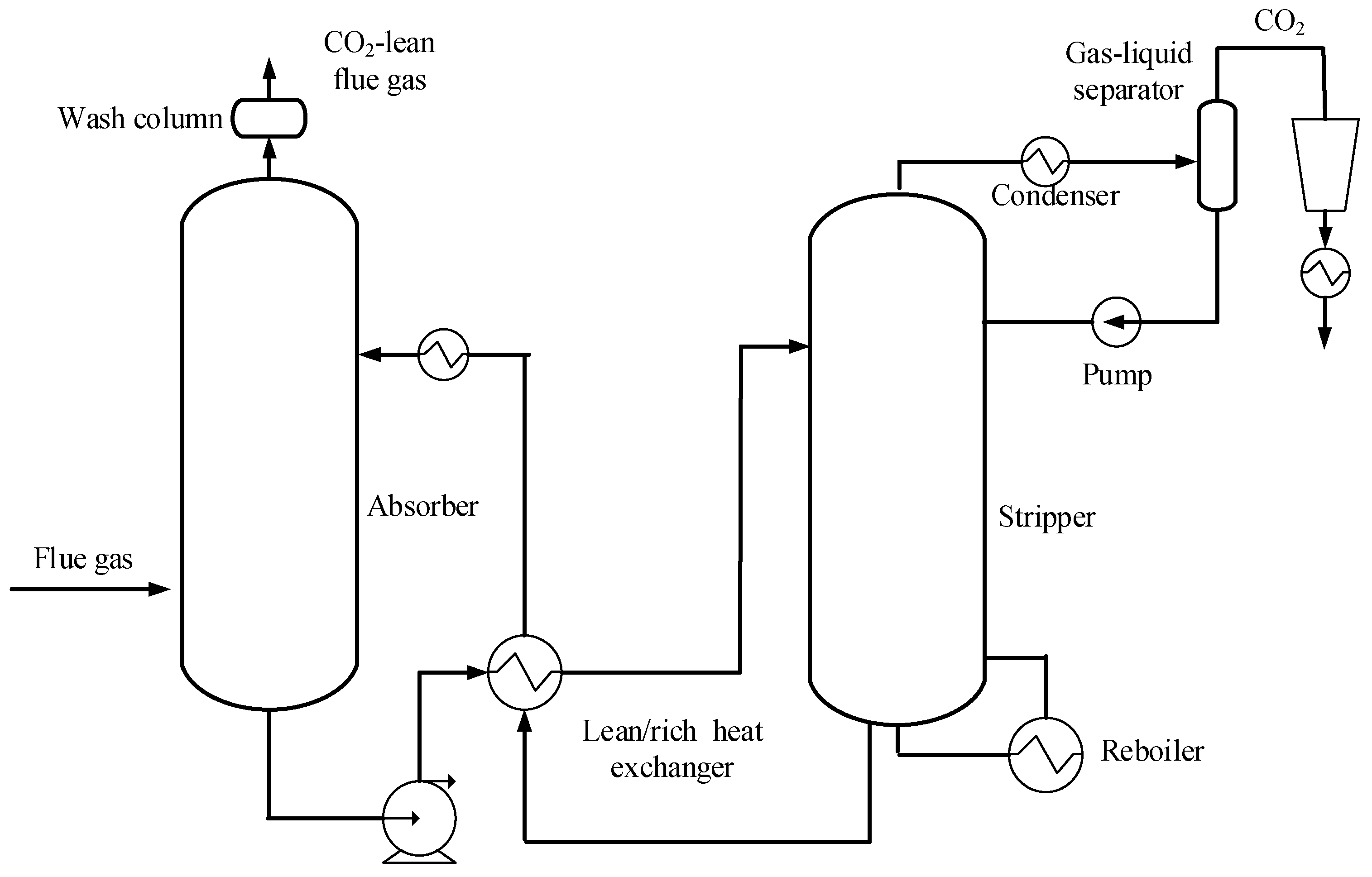

PDF Carbon dioxide capture from existing coal-fired power plants Simplified Process Flow Diagram for Power Plant Modified with the Addition of an Advanced Amine Based CO2 Capture System. The flue gas desulfurization (FGD) system is modified identically for each of the cases with the addition of a secondary absorber to reduce the SO2 content of the flue gas...

PDF W H I C H existing coal-fired power plants would be the best target... Figure 15 | Typical Modern Power Plant Process Flow Diagram. The performance standard under the Regulations for all coal-fired power generation is a CO2 emissions limit of 420 tonnes per GWh, which is equivalent to the emissions intensity level of a modern, high efficiency, base loaded Natural...

Frontiers | Sequential Combustion in Steam Methane Reformers for... SMR Hydrogen Process and CCGT Power Plant. Figure 2 shows a schematic diagram of a The process flow diagram of the integrated configuration consisting of a purpose-built SMR for Figure 2. Schematic diagram of the sequential combustion of natural gas and tail gas in a steam methane...

Thermal power station - Wikipedia Power plant that generates electricity from heat energy. Nantong Power Station, a coal-fired The energy of a thermal power station not utilized in power production must leave the plant in the form The water is pressurized in two stages, and flows through a series of six or seven intermediate feed...

Coal Power Plant - YouTube How a coal power plant works? This video explain the key components of a coal power plant.

An Overview of Combined Cycle Power Plant A Combined Cycle Power Plant produces high power outputs at high efficiencies (up to 55%) and with low emissions. Under normal conditions the inlet system has the capability to process the air by removing contaminants to levels below those that are harmful to the compressor and turbine.

PDF Retrofitting of Coal-Fired • options for federal coal-fired power plant CO2 emissions mitigation research management principally through government/industry partnerships.1. • improvements in post-combustion capture options to include better amines and advanced flue gas capture processes, almost all of which are in the early...

How a Coal Plant Works How a Coal Plant Works. Coal-fired plants produce electricity by burning coal in a boiler to produce steam. The steam produced, under tremendous pressure, flows into a turbine, which spins a The steam is then cooled, condensed back into water and returned to the boiler to start the process over.

0 Response to "41 coal fired power plant process flow diagram"

Post a Comment